Sand and Sports — Winning Performance Goes With the Grain

Ask any athlete about their gear of choice, and you’ll likely hear about the pros and cons of different running shoes, golf clubs or tennis rackets. Both amateur and professional athletes can be very selective about their equipment and will experiment to find the brand or technology that gives them the best outcome. Likewise, the environmental conditions, including the playing surface, can significantly impact sports performance. For golfers, volleyball players and athletes playing on grass or turf, the playing surface can play an important role. You probably know that sand is used to build many sports facilities. You may not know that sand is not “just sand.”

In sports and recreation, players and groundskeepers evaluate sand against competing demands, which vary depending on where and how the sand is used. Physical characteristics, including grain size and shape, affect performance, such as whether water flows through a field or putting green or causes the surface to become soft and unplayable. These kinds of details have an enormous influence on athletes’ experiences.

In this blog, we will dig into the science of sand and why different sports go with different options.

Is the Playing Surface Up to Par?

The United States Golf Association (USGA) has established guidelines for the physical characteristics of greens and bunkers, ensuring optimal playing conditions. Similarly, the American Society for Testing and Materials provides testing guidelines for root zone mixes, the sand and soil mixes used to grow grass on turf fields. Agronomists, groundskeepers and other field specialists use these guidelines and feedback from soil consultants when building or refining a playing surface. Specialized lab testing provides the data to guide their decisions.

Testing for Prime Performance

At BESTSAND™, we rely on the experts at Turf & Soil Diagnostics (TSD) and other testing labs to evaluate our products. We send samples to these partners for a range of testing, depending on the specific application and any challenges the customer may face. “Together, we work to meet customers’ exact specifications,” said Sam Ferro, President of TSD. “This may require testing, adjusting and re-testing until we get it right.”

The following section examines some important sand and soil attributes and how they are measured.

Penetrometer Value — Bunker Sand Testing

Technicians use a device called a penetrometer to measure bunker sand resistance to ball penetration. This reflects qualities like firmness, denseness and compaction. The ball is pushed into a sample of dry, loose sand in a container with rigid sides, as shown in the image below. The force used to push the ball halfway down is called the penetrometer value.

SOURCE: Turf & Soil Diagnostics

Particle Shape

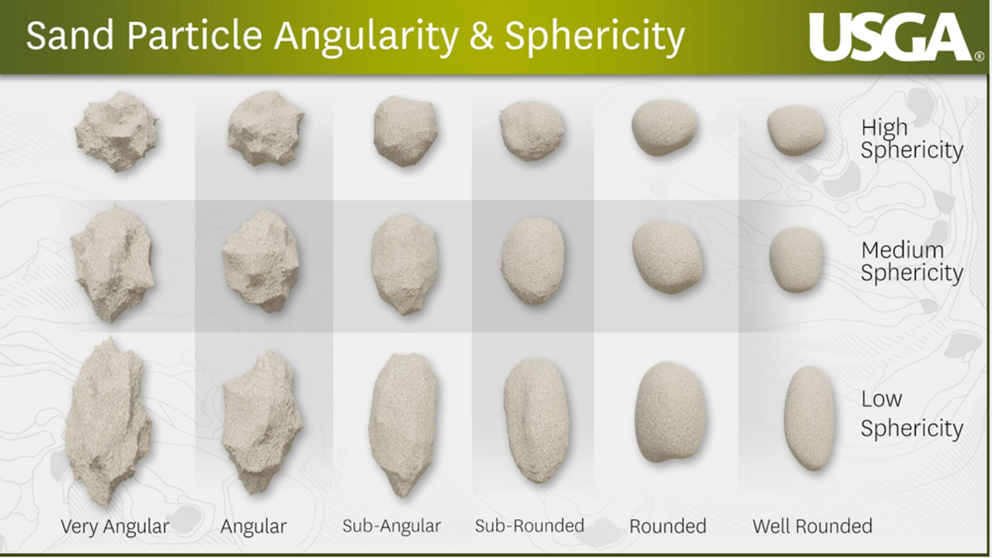

Particle shape is defined by angularity and sphericity (see below). Angularity describes how many edges a particle has and is classified on a spectrum from very angular to well-rounded. Angularity affects compaction; angular sands are preferred for golf bunkers because they compact well and stay in place. Angular sand also provides good resistance to compression. This means that when a golf ball lands in a bunker with angular sand, it is less likely to produce what is called a “fried egg” — a ball sitting in the middle of a small crater formed on impact.

The roundness of a particle falls on a spectrum from high to low sphericity. Rounder sand is better for a sand volleyball court because it’s more comfortable on bare feet. However, a delicate balance between sand softness and firmness is necessary to create a surface that is both comfortable and facilitates jumping.

Particle Size

Particle size analysis defines a soil sample by its sand, silt, clay and gravel content. It also determines the sand fraction, which is the grain size distribution in a sample. To measure this, several sieves are stacked on top of each other, with each successive sieve having smaller holes (see the image below). Sand is poured over the top; the sieves are shaken so the sand moves down, and particles are caught on each one, depending on their size. Technicians then evaluate and report the distribution of particles retained in each sieve. For bunker sand, most of the sand in a sample should be between coarse and fine (0.1 to 1.0 mm) to meet USGA bunker sand guidelines.

SOURCE: Turf & Soil Diagnostics

Infiltration Rate

To evaluate a sand sample’s infiltration rate, or how quickly water passes through it, technicians use a tool known as an infiltrometer. It measures the water passing through a soil sample over time, which is used to calculate the infiltration rate in inches per hour. Typically, the coarser the soil is, the faster it drains. The finer a soil is, the more water it holds and the slower it drains. There are industry guidelines for this, but customers also have their own preferences.

Angle of Repose

Imagine sand flowing through an hourglass. The angle of repose is calculated based on the shape of the pile of sand that accumulates at the bottom. This test evaluates how well sand will stay in place on steep bunker faces. In the lab, dried sand is released through a funnel, and the resulting sand cone is measured to calculate the slope from bottom to top. In general, the angle of repose ranges from 0° to 90°, while for sand, it ranges from 30° to 35°.

From Lab to Field

Each characteristic tested in the lab influences performance in the field, from the golf course to the soccer field and sand volleyball court. With its testing partner TSD, BESTSAND has the expertise and the service to meet customers’ needs across various applications.

Go-To Golf Sands

The varied playing surfaces across a golf course depend on sand for performance and playability. Finding the right sand starts with understanding customer needs. “I only present something to a customer after I talk with them and learn what they are looking for and their budget,” said Terry Gwinn, Sales Manager at BESTSAND. “Then it's about matching the right sand to a particular need, which starts at the quarry.” BESTSAND plants across the country source minerals from quarries with angular sands, which are best for building bunkers and giving greens the right amount of firmness. Rock mined from a quarry is processed — crushed, screened and washed — on its way to becoming golf course-ready.

Sport Sands

Customers building or renovating a sports turf field often look for particular characteristics in a rootzone mix. Based on their needs, BESTSAND works with TSD to achieve the best rootzone recipe that meets their needs. “We’ll send sand and soil amendments to the lab; they will test the components and create a trial root zone mix. Then, the recipe will be used in production, and we’ll test the field blend to ensure it meets the specifications,” explained Gwinn. “Then we do quality control testing to ensure the mix stays consistent over time.”

Testing helps when customers present specific problems for troubleshooting. For example, grass can accumulate organic matter on the surface after years of use and maintenance. “This can cause the surface to become too soft,” noted Ferro. “In that case, it may be recommended to renovate the surface with new sand, or a new root zone mix on the top 3" to 4" of the field.”

The sand on a volleyball court should also have certain characteristics to support players’ comfort and performance. “Good drainage is important, as well as firmness so players don’t slip and softness to avoid skin abrasions when players dive for the ball,” Gwinn said. BESTSAND’s volleyball sand is designed for these characteristics and has an off-white color to reduce glare.

The BESTSAND Advantage

At BESTSAND, we take pride in creating high-quality custom blends that meet our customers’ exact specifications. We understand that athletes are particular about the equipment they use, including the sand they play on, and we strive to provide consistent, high-quality sand that helps both amateurs and pros perform at their best.

You can feel comfortable partnering with us for reliable customer service and quality, whether you need to solve a current turf problem or are building a new facility. We have decades of experience and high-capacity facilities strategically located across the United States. Our experts will work with you and third-party soil scientists to evaluate your unique challenges and find a solution that fits your needs.

Get in the Game

Ready to learn more about our products and services? Contact BESTSAND today.

Sam Ferro from Turf & Soil Diagnostics made a valuable contribution to this blog. Thanks, Sam!