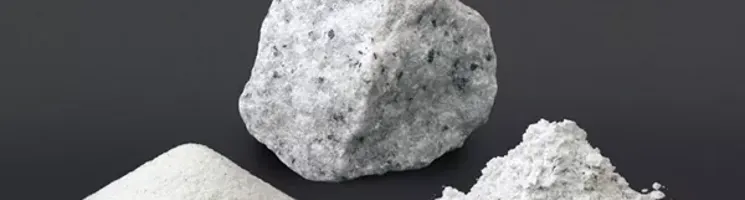

Surface-Treated Functional Filler

MINEX® ST

MINEX (nepheline syenite) surface-treated functional filler was developed to further enhance the already proven properties of MINEX. MINEX ST surface treatments can enhance chemical and stain resistance, washability, adhesion, weatherability and optical clarity. Additionally, it can improve a wide range of other mechanical properties from abrasion to tensile strength by compatibilization of the silicate surface with the host binder system.

Product Highlight

MINEX ST treatments were designed to homogenize the MINEX silicate surfaces for optimal dispersion and cross-linking in both aqueous and solventborne systems. Formulators will obtain the best results when utilized in cross-linkable resin, from light to heavy duty systems where the proprietary surface treatment combinations allow for enhanced wetting, coupling and increased bond strength. MINEX ST increases mechanical and chemical performance by strengthening the binder to filler interfaces.

Mineral:

Nepheline syenite

Product category:

Functional filler

Applications:

Specialty and high end reactive architectural, protective, general industrial, floor, powder, wood and aerospace coatings

Safety:

As regulations increasingly call for reduced exposure to crystalline silica, adhesives and sealants like MINEX ST are preferred for coatings. Analysis confirms that all MINEX ST grades are ideal for improving industrial hygiene.

Flexibility:

MINEX ST is available in three particle sizes (4, 7 and 10) and two functional treatments (A100 and OV100).

Compatibility:

Compatible with an increasing number of waterborne resins, MINEX ST A100 improves properties in solventborne epoxies, as well as 1K self-cross-linking and 2K waterborne systems. MINEX ST OV100 improves properties in solventborne cross-linked systems.

Dependability:

MINEX ST has the same optics, handling, sheen control and color acceptance as MINEX.

Cost efficiency:

MINEX ST can provide cost savings via higher loadings and improved dispersion.

Ease of dispersion:

MINEX ST easily disperses in a wide range of advanced resin systems.

MINEX ST is available in multiple grades to enhance performance in coatings, adhesives and sealant systems. This makes MINEX ST ideally suited for the following applications:

Protective and marine coatings

MINEX ST enhances the chemical and acid resistance, protects against corrosion and improves weatherability in protective marine coatings.

High performance floor coatings

MINEX ST can cross-link into epoxy, PU and polyaspartic floor coatings to improve performance and chemical resistance and lower formula cost.

Specialty and high end reactive architectural coatings

MINEX ST can cross-link into functionalized resins and improve dispersion, stability of suspension, improve washability, weathering and water resistance.

General industrial coatings

MINEX ST can cross-link into epoxy and PU systems to raise solids, improve chemical and weather resistance and lower formula costs.

MINEX ST Overview: MINEX ST Product Sheet

Regulatory Compliance Overview: Safety & Regulatory Brief

Related Stories

Contact Covia today at 1.800.243.9004 or Sales@CoviaCorp.com, or click to fill out this form.